Call 1-800-997-7940

Call 1-800-997-7940

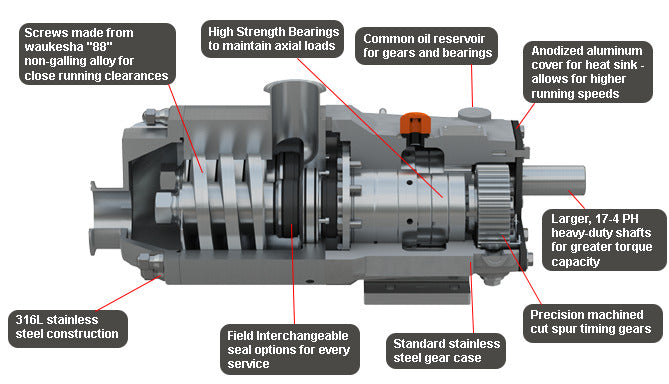

The Universal Twin Screw delivers axial flow with gentle product handling and the ability to pump shear sensitive fluids with larger particulates in lower pressure applications. As the screws mesh together, they form multiple sets of “sealed cavities” which give the pump positive pressure capability to carry product from the inlet to the outlet in a smooth, consistent manner.

| MODEL | SCREW PITCH | DISPLACEMENT PER REVOLUTION | NOMINAL CAPACITY | COVER PORT | BODY PORT | MAX PARTICULATE | MAX RPM |

|---|---|---|---|---|---|---|---|

015-UTS | 16.5 33 44 | 0.02 Gal. (0.08 Liter) 0.03 Gal. (0.11 Liter) 0.04 Gal. (0.15 Liter) | 70 GPM (265 LPM) 105 GPM (398 LPM) 140 GPM (530 LPM) | 2" (51mm) | 1.5" (38mm) | 0.33" (8mm) 0.65" (18mm) 0.44"* (11mm) | 3500 |

030-UTS | 16.8 28 42 | 0.03 Gal. (0.11 Liter) 0.05 Gal. (0.19 Liter) 0.08 Gal. (0.30 Liter) | 93 GPM (352LPM) 155 GPM (587 LPM) 248 GPM (939 LPM) | 2.5" (64mm) | 2" (51mm) | 0.33" (8mm) 0.55" (14mm) 0.83" (21mm) | 3100 |

| 130-UTS | 36.7 55 73.4 | 0.12 Gal. (0.45 Liter) 0.18 Gal. (0.68 Liter) 0.24 Gal. (0.91 Liter) | 300 GPM (1136 LPM) 450 GPM (1703 LPM) 600 GPM (2271 LPM) | 4" (102mm) | 2.5" (64mm) | 0.72" (18mm) 1.09" (28mm) 0.72"* (18mm) | 2500 |

| 220-UTS | 45 60 90 | 0.30 Gal. (1.14 Liter) 0.40 Gal. (1.51 Liter) 0.61 Gal. (2.31 Liter) | 600 GPM (2271 LPM) 800 GPM (3028 LPM) 1220 GPM (4618 LPM) | 4" (102mm) or 6" (152mm) | 4" (102mm)

or 6" (152mm) | 0.89" (22mm) 1.18" (30mm) 1.77" (45mm) | 2000 |

* Double start screws limit particulate size.

NOTE: If operation is required near the maximum allowable RPM, please contact SPX FLOW application engineering for confirmation of the correct pump configuration.

0-3500 RPM speed range. 2" (51 mm) cover port and 1.5" (38 mm) body port sizes; suitable to 375 PSI (25.5 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

NOTE: Dimensions are for guidance purposes only.

1 Shaft key dimension: .187 x .187 x 1.125 in / 5 x 5 x 29 mm

Approximate shipping weight 87 lb. (39 kg.)

| in (mm) | |

|---|---|

| A | 16.40 (417) |

| B | 15.32 (389) |

| C | 10.27 (261) |

| D | 0.875 (22.23) |

| E | 4.95 (126) |

| F | 7.68 (195) |

| G | 7.28 (185) |

| H | 11.84 (301) |

| I | 1.40 (36) |

| COVER PORT | 1.50 (38) 2.00 (51) |

| BODY PORT | 1.50 (38)

2.00 (51) |

| WEIGHT | 87 lbs (39 kg) |

Need help with a custom Twin screw pump configuration? We can help. Contact us and we will make the process simple and easy.

| Language | Download |

|---|---|

| English | Twin Screw Manual (English) |

| Spanish | Twin Screw Manual (Spanish) |