Call 1-800-997-7940

Call 1-800-997-7940

SPX-Flow processing products and technologies provide a wide range of essential capabilities for customers across the food, beverage, and industrial markets. SPX-Flow brands include Waukesha Cherry-Burrell, APV, Bran+Luebbe, Lightnin, and Johnson Pump. Their unique expertise spans generations and engineering disciplines, allowing them to solve complex challenges and create scalable solutions that meet the strategic objectives of the companies that nourish and build our world.

Part of the expansive SPX FLOW collection of world-class process technology brands, Waukesha Cherry-Burrell® (WCB) focuses heavily on the food, dairy, beverage, pharmaceutical, chemical, personal care and industrial processing sectors. WCB engineers and manufacturers positive displacement and centrifugal pumps, sanitary valves, dispersion equipment, and the legendary Votator® scraped surface heat exchanger product lines. Durable in construction and highly optimized to tackle the toughest applications - customers enjoy elevated levels of operational efficiency and accelerating throughput rates, without compromising product quality.

Featuring state-of-the-art, low maintenance designs, plus robust and easy to clean stainless steel construction, this equipment can easily manage a wide range of product viscosities and pressures. They are able to maintain consistent results with processed food/beverage products exhibiting the texture uniformity and quality that customers expect. In addition, these components typically meet industry benchmarks in operational efficiency - not only keeping running costs down, but also causing less ecological impact too. These products are backed up by a highly experienced and responsive engineering support team.

Wayland Industries provides the highest quality stainless steel sanitary fittings, valves, and tubing to distributors throughout North America. Their products are made from T304 and T316L stainless steel, are 3A sanitary standard, and meet the highest specifications of compliance in the industry.

We stock a large selection of Wayland fittings and gaskets, but can also custom order more.

View the full Wayland Catalog to see our full selection || PDF

Unisource Manufacturing offers a full range of food grade sanitary hoses that meet the applicable FDA,

3-A or, USDA standards. All Unisource stainless steel crimp fittings are 360 degrees radially crimped

which doesn’t deform the interior of the stainless steel hose barb, thus maintaining purity. The design of

the barb promotes full flow of the product. Compared to externally banded fittings, this style doesn’t

require disassembly for cleaning.

Food grade rubber hose options include a general purpose suction and discharge hose, crush resistant

hose, high flexibility hose, and one with a plastic external helix for easy drag across floors.

PVC and silicone hoses come in clear or opaque with options of braided or wire reinforcement.

Nether Industries can custom build hose assemblies with any combination of stainless steel fittings

needed, from Tri-clamp, bevel seat, camlock, din, I-line and more. We can incorporate elbows and

reducers as required for your application.

ABB Baldor-Reliance motors are the industry best. Nether currently stocks ABB Baldor-Reliance Food Safe stainless-steel motors.

ABB’s Baldor-Reliance Food Safe stainless-steel motors are designed to perform longer than any other industrial electric motor available today. Designed for food processing where reliability and cleanability are of utmost importance in an intense, caustic cleaning environment. Baldor-Reliance Food Safe motors are designed to perform reliably - at maximum efficiency - around the clock and be effectively cleaned to a hygienic level to ensure uncompromised food safety.

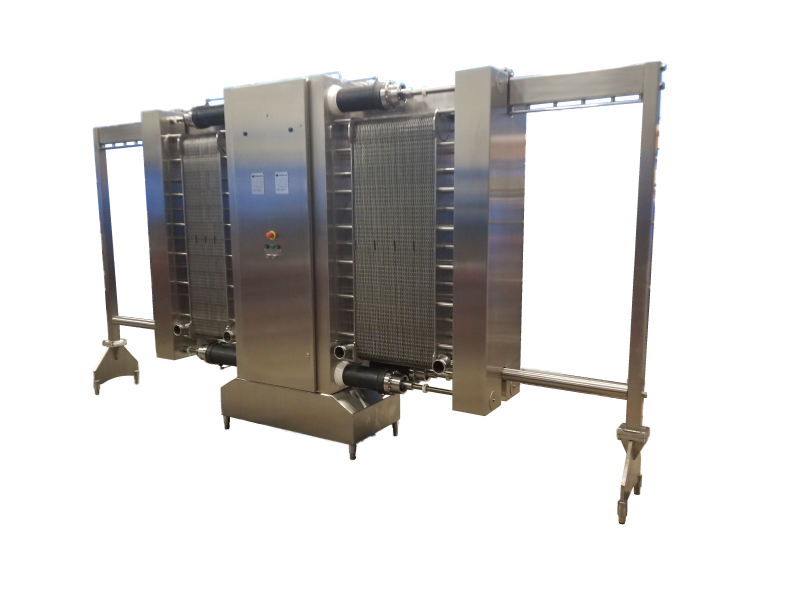

For nearly three decades, Thermaline has manufactured innovative heat transfer

solutions made in the USA and distributed worldwide.

They take pride in creating jobs and value in our community while providing robust

and innovative heat exchange equipment. From raw material to finished product,

Thermaline’s team of skilled engineers and fabricators consistently produce some

the best heat exchangers available.

Thermaline is constantly improving their processes to meet today's demands, keep

lead times low, and prices competitive. Their proprietary online tools allow

customers the power to design, receive a quote or purchase in stock equipment

instantly and hassle free.

For the last 30 plus years, they have never wavered their strive for improvement, honing their craft and gathering invaluable industry knowledge. They are experts in heat exchangers, and they work with the production plants of the nation's biggest brands for food processing, dairy, beverage, breweries, distilleries, cannabis and bio/pharma. Thermaline is the industry standard in heat exchanger engineering, and are certified by ASME, 3-A AND BPE. They build all products to meet stringent consumer safety standards and energy consciousness. Thermaline is a relatively small, nimble team, which allows them to tailor every product to the project you’re working on.

Achieving the balance between energy efficiency, optimal performance, and dependability is a complicated equation that is easily solved with our years of experience. Our plate heat exchanger line caters to a multitude of industries including food, beverages, dairy, condiments, wine, beer and also industrial applications.

NORD offers full-featured drive solutions capable of the most difficult requirements. Their gear units are industry-leading and high-quality. All NORD’s are precisely configured to meet exact specifications.

In the rare case that standard components won’t meet needs, their in-house engineering team will design custom components or a complete customized system.

Founded in 1937, Chicago Stainless Equipment is the oldest and one of the largest manufacturers of precision instrumentation. Their applied experience produces outstanding gauges, thermometers, and thermowells.

As a Chicago Stainless Equipment distributor, Nether Industries Inc. can meet all your instrumentation needs.

Chicago Stainless brochure || PDF

RathGibson’s sanitary tubing exceeds

ASTM A270 S2 and 3A specifications

and most user specifications. It is

manufactured from the finest quality

stainless steel materials made

exclusively to the RathGibson melt

criteria, and formed by the RathGibson

Micro-WeldTM process to assure weld

seam integrity and industry leading

ID and OD finishes to low Ra

values.

RathGibson leads the

industry in manufacturing the highest

quality welded sanitary tubing,

backed with technical expertise,

advanced manufacturing and

polishing capabilities, and unmatched

service before and after the sale.

All standard sanitary tubing sizes

are available in 1/2" (12.7 mm) to

8" (203.2 mm) OD in stock 20' (6.1 m)

lengths.

Tubing for

Industrial/

Commercial

Applications || PDF

A270 Sanitary Stainless

Steel Tubing|| PDF

True15™

Electropolished Stainless

Steel Tubing || PDF

A270-BPE

High Purity

Stainless Steel Tubing || PDF

Nether Industries is the Northwest Preferred Distributor for Graco’s sanitary products. Graco’s new SaniForce line saves you time and money by pumping the most difficult materials – quickly and safely! For Graco’s sanitary processing equipment, contact Nether for your needs.

Nether Industries is the regional supporting distributor for Admix agitators and blending systems. Admix provides solutions and expertise in both liquid blending applications and powder-into-liquid applications. Our sales team is equipped with a 5 gal Admix Demo Unit that we can bring onsite to blend a test batch and demonstrate the efficiency of the proprietary Rotosolver head. Admix’s line of domestically manufactured agitators, shear pumps, and blending tables, is designed to decrease the blend time of a process while achieving the same, or better, product incorporation.

Endress+Hauser is a global leader in measurement instrumentation, services and solutions for industrial process engineering. They provide process solutions for flow, level, pressure, analytics, temperature, recording and digital communications, optimizing processes in terms of economic efficiency, safety & environmental impact. They work with various industries, including chemical, food & beverage, life sciences, power & energy, mining, minerals & metals, oil & gas and water & wastewater.

Quality Sourced Manufacturing, Inc. (QSM) is a leading manufacturer of stainless-steel valves and automation technologies. Known as Tru-Flo Valves and Automation, their products are found in food processing, dairy, beverage, pharmaceutical, pet care and many other industries around the world. They build high quality products with excellent service and prices.

Tru-Flo Catalog || PDF

Nether Industries is a stocking distributor for DSO Fluid Handling, manufacturer of quality FDA/3A seals in the food processing industry. DSO offers a line of color-coded tri clamp gaskets, allowing for designation of allergen lines or specialty process applications.

Murzan Diaphragm pumps offer total stainless steel construction in a simple and sanitary design. The ease of use is a feature when troubleshooting or servicing these high capacity pumps that perform well in suction and discharge applications of flowable products.

WEG is globally regarded as a leading manufacturer of energy efficient electric motors, variable speed drives (AKA variable frequency drives), and industrial systems. Nether currently stocks WEG CFW08 variable frequency drives. WEG CFW-08 VSDs are easy to install and operate. The WEG CFW-08 Series is intended for speed control of three-phase induction motors. Designed for exclusively industrial or professional use, the VSD incorporates the most advanced technology and full features in a compact product, beyond a set of special functions available. We can fulfill your WEG stainless steel motor and VSD needs.

Axiflow Technologies, Inc., in partnership with Jung Process Systems, brings to the sanitary market a revolutionary pumping technology that sets a new benchmark for a wide range of pumping applications. The Axiflow/Jung relationship combines German precision engineering with American innovation & process experience. They offer viable solutions to many difficult process problems often experienced with positive displacement pumps. The Axiflow solution far exceeds current industry standards and expectations.

Axiflow/Jung maintains 3A and EHEDG certifications for all pumps in our offering. Axiflow pumps and parts are manufactured in Kummerfeld, Germany, and assembled in the United States. A complete inventory of pumps, assemblies and spare parts are located at various Axiflow facilities throughout North America. Demo and trial pumps are available for testing at customer facilities. Whether your needs call for timing product through a high pressure drop pasteurizer, stuffing a homogenizer with a high viscosity liquid, or simply transferring a shear sensitive slurry or emulsion, give Axiflow a try.

Mueller Water Products, Inc. is a leading manufacturer and marketer of products and services used in the transmission, distribution and measurement of water in North America. Their broad product and service portfolio includes engineered valves, fire hydrants, pipe connection and repair products, metering products, leak detection, and pipe condition assessment. They help municipalities increase operational efficiencies, improve customer service and prioritize capital spending, demonstrating why Mueller Water Products is Where Intelligence Meets Infrastructure®️.

When you invest in water infrastructure, smart really matters, from the products themselves to the people behind them. Using rock solid materials and ground-breaking technology, our products and services are designed and engineered for the long run. That means lasting value for the communities and contractors who choose solutions offered by the Mueller Water Products group of companies – value that ultimately can translate into cost savings.

Sani-Matic, Inc. designs and manufactures automated sanitary process cleaning equipment, from Clean-Out-of-Place (COP) Parts Washers and cabinet washers, such as the SaniCab and PharmaCab, to Clean-In-Place (CIP) Systems, and sanitary components that provide a complete clean.

It’s been that way since the Sani-Matic story began in 1943. That’s when they developed a Clean-Out-of-Place (COP) Parts Washer for the dairy industry and began a precedent of high-quality equipment innovation at the forefront of automating sanitary cleaning processes.

Protect Product Integrity, Increase Productivity

Every sanitary process, whether it is a food, beverage, pharmaceutical, or personal care process, requires particulate straining to protect product integrity and processing equipment. With Angle-Line Strainers, you can do that while also increasing productivity.

The Sani-Matic Angle-Line Strainer

• Can be cleaned without removing it from the process line, increasing production uptime.

• Is 3-A certified when used with a perforated insert.

• Allows for both standard and reverse process flow by changing the strainer element frame.

• 4″ body Angle-Line Strainers have Canadian Registration Numbers (CRN)

• 4” body Angle-Line Strainers and 6” body High-Capacity Angle-Line Strainers are available to meet different process volume needs.

All of Sanimatic static spray balls are manufactured in the U.S. for quick turnaround times—and we stock several standard designs for immediate availability. Standard static spray ball designs are 3-A certified when used with a wraparound clip.

SB-1

SB-2

SB-3. Custom spray ball patterns

SB-4

SB-5

SB-6

Feldmeier Equipment is a respected supplier to some of the most elite companies worldwide in their respective trades. From pharmaceutical, biotech, and cosmetic clients to brewers and food, dairy, and beverage processing facilities, the Feldmeier name has become a trusted resource for quality, dependable stainless steel processing equipment.

From the advent of the Triple Tube Heat Exchanger, to the Spray-Up silo cleaning system, and most recently the Feldmeier’s entire Farma Mixer agitation line; Innovation has been, and will continue to be, their family tradition.

Dixon is a major leader in the food and beverage processing industry. After acquiring Bradford Fittings, Dixon Sanitary provides a full line of 304 and 316L stainless steel fittings, valves, and seals. Whether it is a cam and groove fitting or a sanitary swivel, Nether can provide all things Dixon.

Access Dixon’s product catalogue here || PDF

Walker Engineered Products offers highly specialized consulting to the dairy, food and beverage, pharmaceutical, chemical, and personal care industries as they seek to deploy precisely engineered stainless steel tanks, process vessels and silos.

With decades of experience in cutting-edge agitation technologies, heat transfer solutions, specialized alloys and regulatory compliance, they create highly customized solutions that work better, last longer and deliver better return on your investment.

Saunders is a global leader in providing valve solutions for industries where resistance to corrosion, abrasion, contamination, and trouble-free operation are imperative.

Saunders offers bodies with weld and clamp ends to meet all global tube and pipe specifications. This includes OD tube, DIN, ISO, SMS, and schedule pipe. Standard body material for all forged bodies is stainless steel dual certified to 316L (ASTM A-182) and DIN 1.4435, with the additional requirement of controlled sulfur per ASME-BPE standard.

Nether Industries is a regional distributor for Rubber Fab products, offering elastomeric solutions to your sanitary process. Manufacturer of FDA/3A seals, hose, and 3A hose assemblies, Rubber Fab provides innovative solutions for the food processing industries such as Metal Detectable and X-rayable gaskets and O-rings.

For more than 25 years, Pro has focused on producing a premium Packaged Chiller System for anyone looking to move beyond the off-the-shelf solutions and move up to high quality equipment built for their specific needs.

Pro’s engineering and design team takes a “ground up” approach for every single product they’ve developed. They don’t stop until they’ve made sure that every single individual component, including the overall system design, will serve the required needs of every application.

Pro’s standard product lines of Packaged Chiller Systems deliver a Leaving Fluid Temperature range from +20° F to +35° F in design ambient up to 100° F. Pro’s also produced systems for numerous custom applications requiring fluid temperatures as low as 0 F up to +70 F located in ambient conditions over 120 F. Pro continuously seeks out new and emerging applications by applying the same commitment to system efficiency, serviceability, and reliability.